PVC Artificial Leather Production Smoke Filtration with Electrostatic Precipitator

1 PVC Artificial Leather Production Smoke

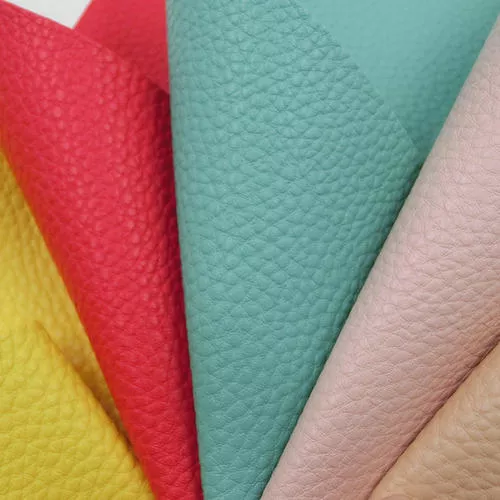

PVC artificial leather, also called synthetic leather, is a material produced to replace authentic leather for clothing, shoes, car, or furniture decoration.

When PVC leather raw material is baked at the high-temperature foaming furnace, the solvent in the mixture volatilizes greatly and forms oil-bearing fume which contains DOP mainly as well as flame retardants, xylene, etc., and the smell is irritant. Therefore, very heavy smoke will be produced in PVC artificial leather foaming oven. These smokes will be extracted by exhaust fans at top of the PVC leather foaming oven, then discharged via ventilation duct and chimney.

A 20~25 meter long foaming oven can produce up to 200L oily air pollutants PER DAY!

2 What Should and Can We Do to the Smoke Pollution from PVC Leather Production Line?

Usually, our customers have the below three main needs:

1 Purify the strong smoke from the PVC foaming oven before it is discharged into the air.

2 Collect valuable oil for recycles. Saves cost for PVC leather production.

3 Heat recovery function to save energy and cost.

Luckily, we have the perfect solution to the PVC leather production smoke to fulfill customers’ needs 100%.

Ask Our Experts for Proposal and Quotation for PVC Leather Smoke Filtration System

3 PVC Leather Production Smoke Emission & Fume Control System Selection

When making PVC leather, it needs several procedures. In the first place, knitting fabric will be coated with plastisol which consists of PVC resin, DOP, plasticizer, and other components, and then made smooth by slicker. Second, the smooth-coated fabric will be heated in foaming ovens. Then a grained surface was given to the material by passing it between suitably embossed rollers. After cooling, PVC artificial leather can be got.

Take the production of common PVC leather as an example: among the entire process, vast amounts of fume will be produced in PVC foaming ovens. The fume consists of DOP and a little other dissolvent.

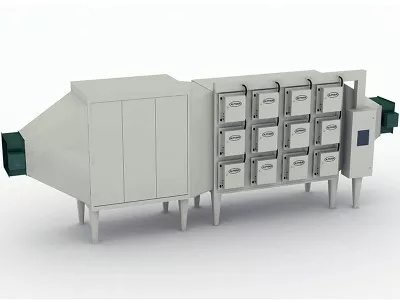

1) In view of the features of the fume, we choose the advanced electrostatic precipitator technology to deal with the fume and collect the valuable oil from the fume.

2) When dealing with the high-temperature smoke from the PVC leather foaming oven, we need to cool it to 50℃ before purifying the fume by electrostatic precipitator.

4 Smoke Filtration and Oil Collection System Design

The high-temperature smoke produced in PVC leather foaming ovens will be extracted to the heat exchanger and be cooled to 50℃. After that, the smoke will be “filtered” by ALPHAIR™ electrostatic precipitator. In this process, most of the oil in the smoke will be filtered and collected (Efficiency: ≥95%). By doing so, the fume will become almost clean air and will be extracted out by exhaust fan. Fresh air can also be heated by a heat exchanger for heat recovery. According to our customers’ feedbacks, our PVC leather production smoke filtration and oil collection system cost can be returned in about half a year via collected oil and heat recovery.

5 Contact Us Now to Solve Your Air Pollution Problem

Please don’t hesitate to contact us by email support@alphairesp.com if you have any interest in this system.