Your Best Electrostatic Precipitator Supplier in China

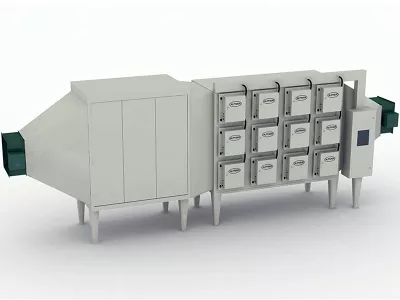

Exhaust Air Purification Solution | Smoke Pollution Control | Commercial Kitchen Smoke Filtration | CNC Oil Mist Collection

Reliable Electrostatic Precipitator Supplier in China – 30 Years of Expertise

Exported to 50+ Countries. Trusted by customers in Japan, the USA, Germany, the UK, Italy, and more.

As a leading electrostatic precipitator supplier, ALPHAIR specializes in commercial kitchen exhaust filtration and metalworking oil mist purification, along with solutions for barbecue smoke, textile production, PVC leather manufacturing, and DOP oil mist recycling. Our products meet ISO9001, ISO45001, ISO14001, CE, ASHRAE 52.2, and EN779 standards, ensuring high filtration efficiency. We provide OEM & ODM services, along with technical support, installation guidance, and logistics assistance. With exports to the USA, UK, Germany, Japan, Canada, and beyond, ALPHAIR is your reliable partner in advanced air purification technology.

High-Efficiency Technology

Tailored OEM Solutions

Flexible OEM and custom branding to help build your brand.

Competitive Pricing

Fast Delivery

Expert Pre-Sales Consultation

Comprehensive Dealer Training

Responsive After-Sales Service

Strict Quality Management

Superior Smoke & Fume Filtration Solution

Commercial Kitchen Smoke

BBQ & Grilling Smoke

Metalworking Coolant Mist

Industrial Exhaust Fumes

Our Filtration Products with Electrostatic Precipitator Technology

Happy Users

FAQ on Our Company

Our factory is based in Dongguan, Guangdong, China. It is only about 1.5 hours from Guangzhou or Shenzhen by car. You are welcome to visit us in person or schedule a virtual tour of our production facilities.