Heat Treat Fume Purification Solution

Air Purification System for Fume from Quenching and Tempering Process

Fume (or oil smoke) is a derivative of heat treatment, which has a large relative molecular mass and can seriously pollute the air quality and cause unpredictable damage to the ecological environment when it escapes into space. Therefore, strict environmental protection measures should be taken, and the most effective collection and treatment methods should be developed according to scientific methods. The article introduces the common heat treatment fume treatment solutions and compares different heat treatment fume purification methods.

Chapter 1 Overview of Heat Treatment Fume Issues

Fume or smoke is an important pollutant in the heat treatment process, and the main source of fume generation is the tempering furnace and open quench oil bath. Due to the difficulty of tempering and quenching oil fume collection, it makes the heat treatment workshop environment poor. Air pollution has become a social concern, in order to achieve the sustainable development of the heat treatment industry, we must solve the problem of soot pollution. In recent years due to air pollution caused by personal health damage events continue to appear, people pay more and more attention to the hazards of air pollution, the national pollutant emission requirements of various industries are becoming more and more stringent, heat treatment industry, if not to solve the problem of oil pollution, will cause great constraints and impact on the development of heat treatment industry.

1.1 Heat Treatment Fume Generation

Heat treatment process is indispensable in improving the quality and strength of parts. However, in the quenching and tempering process of heat treatment process, high temperature parts cooled with oil will generate a lot of oil fumes.

1.2 Hazards of Heat Treatment Fumes

Heat treatment fume is a multi-phase gas-like fluid, mainly atmospheric components, oil particle diameter is generally between 0.1 ~ 102μm, density of 1.30 ~ 1.34kg/m3 (air density of 1.239kg/m3), mainly in the form of liquid aerosols and solid aerosols exist, the natural settlement rate is very small, can be suspended in the air for a long time.

When the workpiece is quenched in oil, a large amount of soot is generated in a short period of time, of which larger soot particles will automatically settle and adhere to equipment and ground walls, forming a potential safety hazard; small soot particles will be suspended in the air, causing the workshop to be filled with smoke and enter the human respiratory system, causing damage to the health of employees.

Chapter 2 Collection of Heat Treatment Fumes

Generally, a fume hood is set up at the quench tank to collect the fumes generated during the quenching process. Quenching oil pool fume collection is a key point for the successful application of heat treatment fume purification system, so the design of the hood is critical, not only to consider the collection of fumes, but also to combine the actual quenching process, equipment layout and ease of operation of the owner to do a comprehensive consideration of non-standard design, the best hood to collect good results, but also to run stable, economic and beautiful.

Fume hoods and piping systems are made of high-quality carbon steel, such as multiple quenching pools share a set of oil and fume purification treatment system, the entire piping system design to consider the use of pneumatic switching valves, electric executive control valves, fire valves, thermocouples and complementary cold air devices, so as to achieve automatic system air volume switching and distribution, to achieve energy saving and consumption reduction function.

Chapter 3 Comparison of Major Heat Treatment Fume Purification Solutions

3.1 Mechanical Filtration

Working Principle: The use of inertial collision or cyclone separation to remove large particles in fumes, commonly used mechanical separation equipment are dynamic interceptor and cyclone separator.

Advantages: simple equipment structure, easy maintenance, low investment, low operating costs.

Disadvantages: the particle size of small fine particles removal efficiency is low, can not remove VOCs gaseous pollutants, the need for frequent cleaning, cleaning fluid is easy to form secondary pollution.

3.2 Water Scrubber

Working Principle: In the wet scrubber purification process, the heat treatment fume is in close contact with the absorbent liquid, which transforms the particulate matter in the fume gas into the liquid phase. The most representative wet fume cleaning methods are fume hood and tower shower.

Advantages: low cost

Disadvantages: The drawback of wet type fume cleaning is that the waste liquid needs to be treated or washed, and the overall efficiency of cleaning is only about 80%.

3.1 Electrostatic Precipitator for Heat Treatment Fume

Working Principle: Heat treatment fume particles is ionized in the high-voltage electric field so that the fine particles are charged and move toward the dust collection pole under the electric field force and are coalesced and deposited at the dust collection pole, so that the fume is purified.

Advantages: Compact, high purification efficiency, usually up to 95% or more, and relatively small pressure drop. It is widely used and has a high market share.

Disadvantages: Regular cleaning and maintenance is required. Of course, because the cartridge can be cleaned, the cost of cartridge replacement is eliminated. It is the most ideal technology for grease management at present.

To sum up, industrial electrostatic precipitator is the best solution for heat treatment exhaust gas and the most widely used technology.

Chapter 4 Application of Electrostatic Precipitator in Heat Treatment Fume Systems

4.1 Heat Treatment Fume Purification Flow

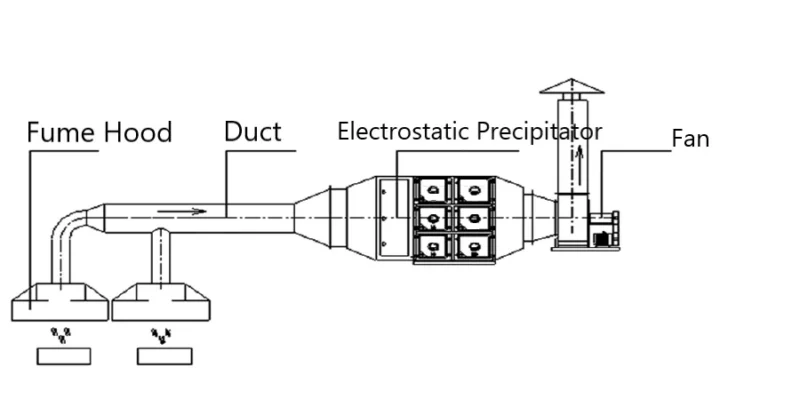

The whole system, under the power of the fan, collects the oil fumes generated during the quenching of the heat treatment oil pool through the fume collection hood and pipeline, and the oil fumes pass through the fire valve and enter the rectification guidance system to ensure that the oil fume exhaust gases enter the electrostatic oil fume purifier more evenly, and the purified gases are discharged by the high-altitude chimney to meet the standards.

4.2 How Does Electrostatic Precipitator Purify Heat Treatment Fume?

First step: Larger particles such as large impurities, oil particles, etc. are trapped on the mechanical filtration device.

Second step: Fine particles are ionized and positively charged when they pass through the ionizer, i.e. the high voltage ionization zone.

The third step: A collector consisting of an aircraft alloy aluminum plate is used to adsorb the positively charged fine particles. As the charged particles pass through the aluminum plate collector, they are pushed by the positive plate to the opposite negative plate, and thus firmly adsorbed on the surface of the negative plate, where most of the particles accumulate, forming droplets that will accumulate on the equipment’s oil catch pan and then drain through the oil drain hole.

4.3 ALPHAIR™ Industrial Electrostatic Precipitator for Heat Treatment Fume

The ALPHAIR electrostatic precipitator uses a two-stage electrostatic technology with an ionization zone and a dust collection zone. The ionization zone charges the particles, which are then separated from the air by an electrostatic field, and the collection plate traps sub-micron particles, ensuring clean air from the unit.

- Adopt integrated structure equipment, easy to install, easy to use and no consumables.

- Adopting advanced automatic control technology, which makes the operation of the equipment simple and effective.

- The oil smoke exhaust gas treatment effect is good, the emission concentration ≤5mg/m3, purification efficiency ≥99%, reaching ultra-low emission index, in line with national environmental protection requirements.

- The oil liquid purified and collected by the electrostatic grease cleaner can be recycled, and there is no secondary pollution.

Inquiry Now!We are ready to help.